Monitor Basics in Plain English

EIZO Optical Bonding

What makes a monitor screen readable in bright ambient environments? The brightness of the monitor, the contrast ratio, and the way light interacts with the surface all determine how visible the screen is in different lighting conditions.

EIZO has an in-house production line for optical bonding, a process that provides LCD monitors with increased visibility and durability. Producing optical bonding in-house allows EIZO to continue to meet the needs of specialty markets while ensuring that each product maintains high quality standards.

What is Optical Bonding?

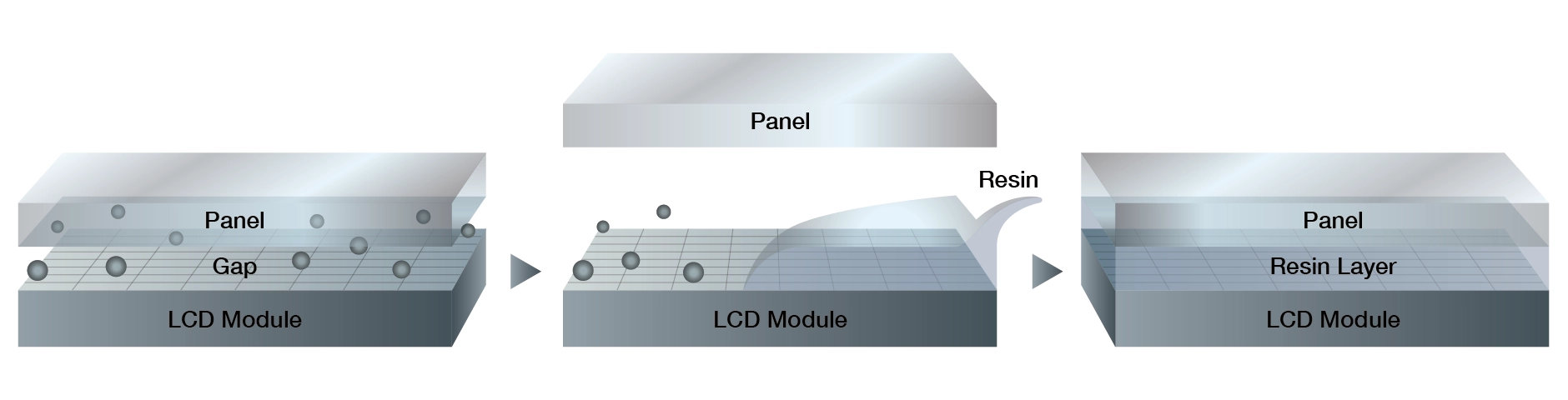

There is a small gap of air that lies between the LCD module and the cover glass or touch panel of a monitor. Optical bonding is a process in which a layer of resin is used to fill the gap, adhering the two together. Filling this gap improves visibility of the screen and increases durability.

Contrast Ratio Comparison

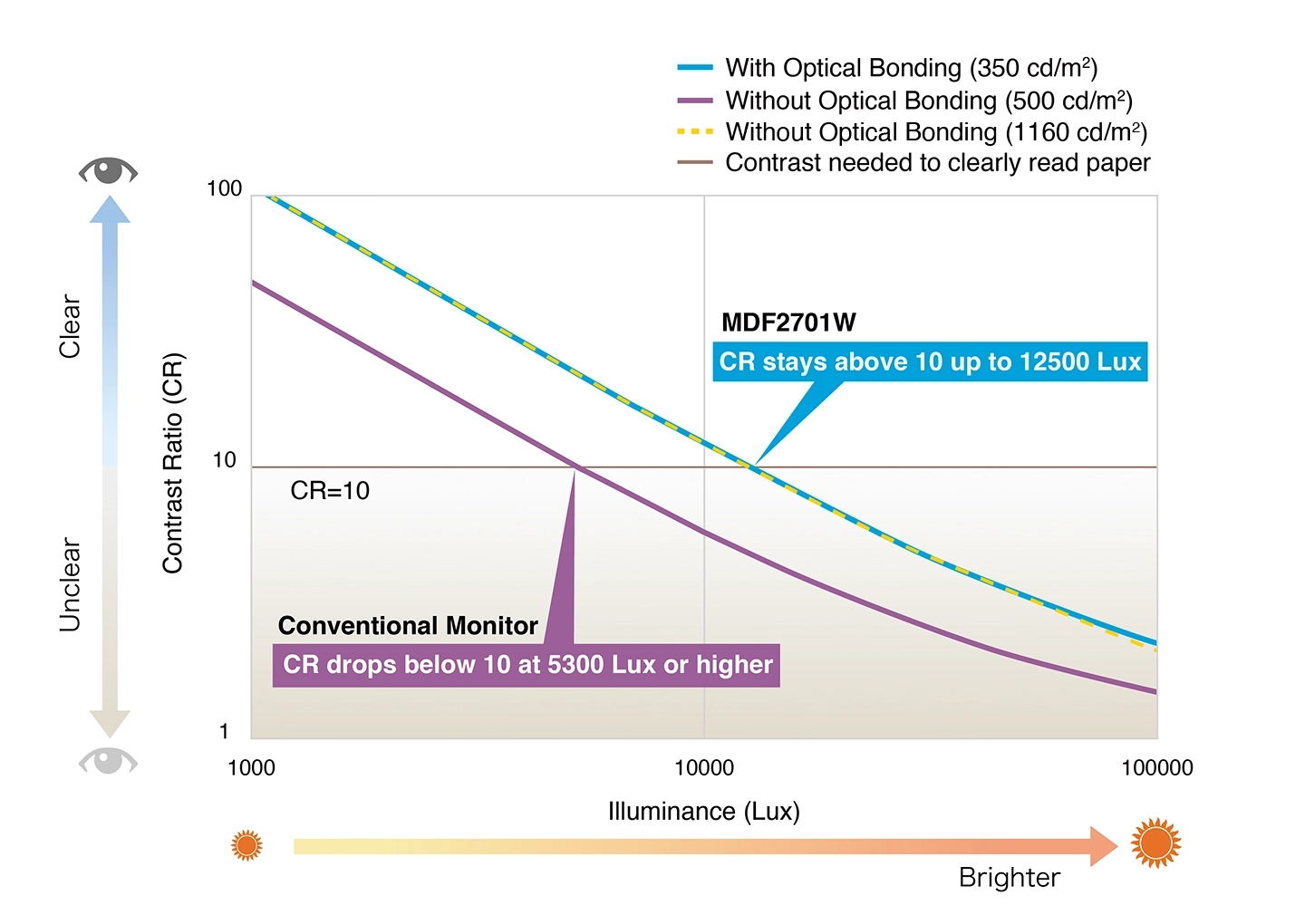

Contrast Ratio (CR), defined as the ratio of the luminance of white to black, is one of several factors that determine the visibility of a monitor's screen. 10 CR (10:1) is the threshold at which text on paper remains legible. Anything below that becomes difficult for the human eye to discern. Using this as a reference, we measured the CR of two monitors.

The following table compares the CR of the DuraVision MDF2701W maritime monitor (with optical bonding, 350 cd/m2) and a conventional maritime monitor (without optical bonding, 500 cd/m2) when viewed under specific lighting conditions (measured in lux). The results show that the monitor with optical bonding and a luminance of 350 cd/m2 has better visibility than the monitor without optical bonding and a higher luminance of 500 cd/m2.

The CR of the monitor without optical bonding drops below 10 when the ambient light reaches approximately 5,300 lux, but the MDF2701W with optical bonding was able to maintain a CR above 10 up to 12,500 lux, meaning that a monitor with optical bonding is able to maintain clarity up to a higher threshold of ambient brightness. A monitor without optical bonding would have to have an estimated luminance of approximately 1160 cd/m2 to achieve a comparable result to the same monitor with bonding.

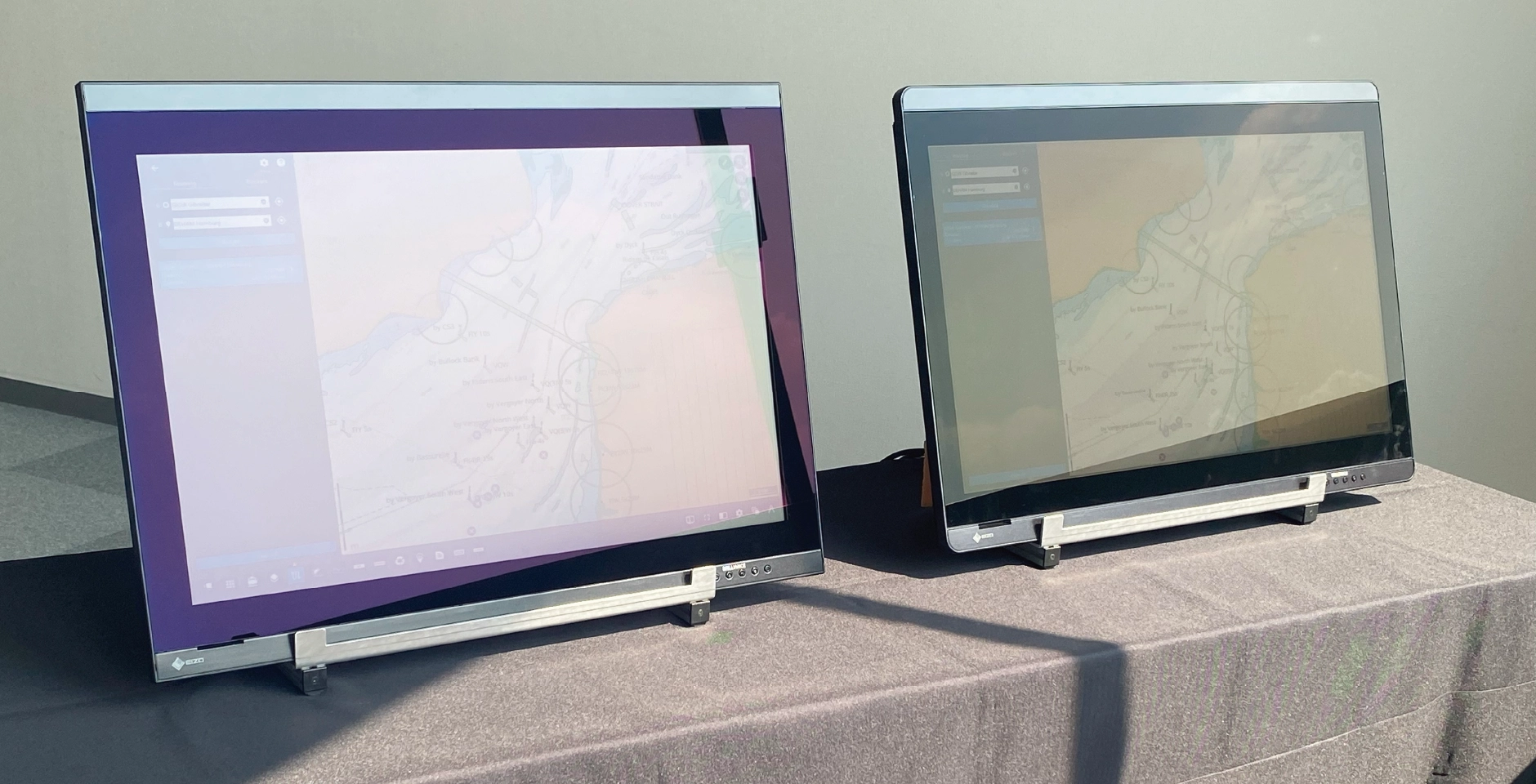

Left: Monitor without Optical Bonding and 500 cd/m2 (with protective glass)

Right: MDF2701W with Optical Bonding and 350 cd/m2 (with protective glass)

Results of EIZO's in-house testing as of April 2024.

Measurements were taken according to IDM (Information Display Measurements Standard) 15.4, which is standardized by the SID (Society for Information Display).

Benefits of Optical Bonding

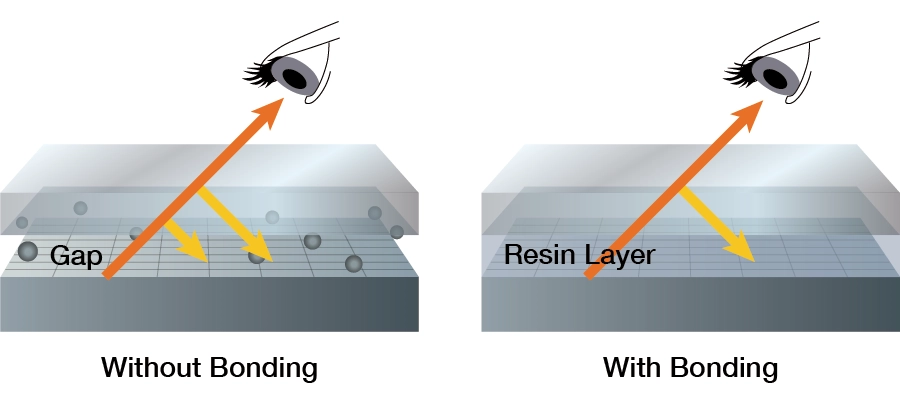

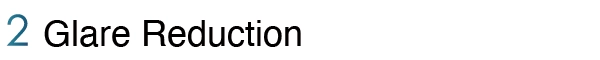

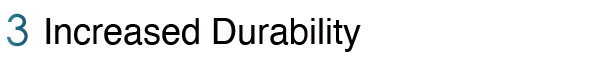

Images shown on a monitor are reflections generated by light from the LCD module passing through the gap and the panel. The gap and panel have different refractive indexes, causing the light to bend when it passes through them. This results in a loss in its intensity, affecting the screen’s readability.

By adhering the LCD module and panel together with optical bonding, the transmission of light is increased, improving the visibility of the display. This is useful when viewing a monitor with bright ambient lighting conditions.

When light from an external source passes through the panel and the gap, refraction causes some of it to be reflected back, creating glare on the screen. The increased light transmission of a screen with optical bonding significantly reduces glare from external light sources.

The reduced glare that optical bonding provides makes it an ideal option when viewing a monitor outdoors or in environments with an intense direct light source.

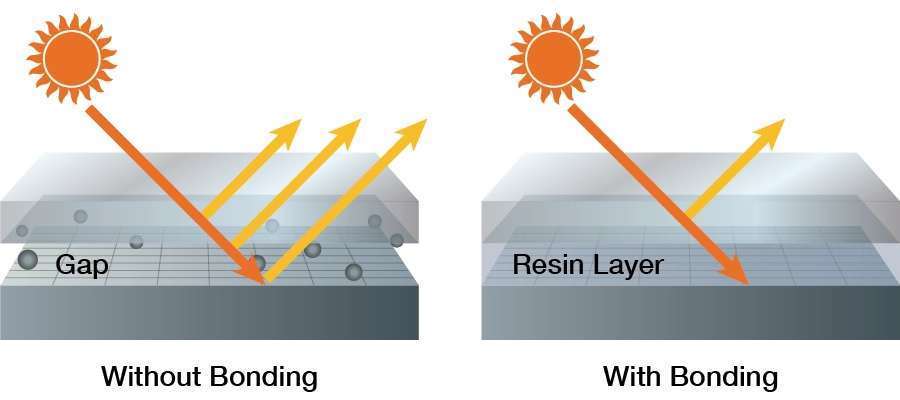

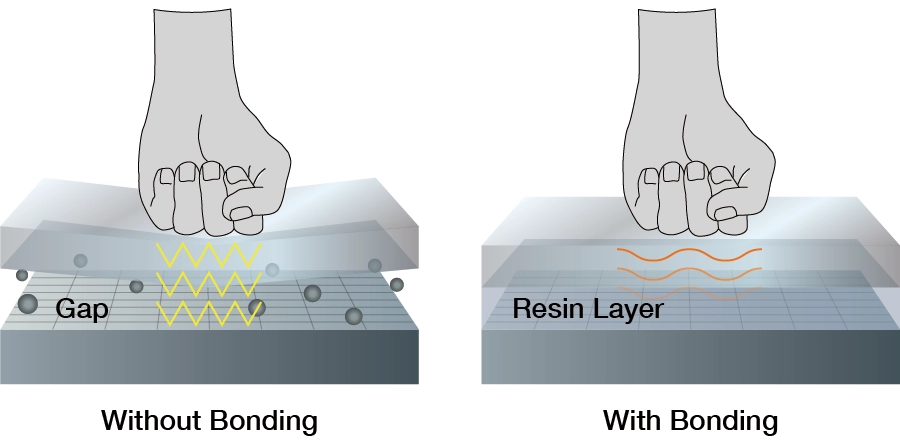

The additional resin layer in optical bonding also provides increased physical durability to the screen. Eliminating the gap between the LCD module and the panel increases the screen’s resistance to scratches, dust, and fluids.

This provides high durability for use in public access areas, factories, or other environments where the monitor is routinely used.

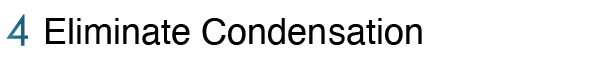

In environments with wide temperature ranges, it is common for condensation to cause screens to become foggy from moisture that penetrates the air gap. A monitor with optical bonding fills the gap to prevent condensation from occurring for improved readability.

This makes optical bonding ideal for ships and offshore structures, warehouses, aircrafts, and other environments that experience extreme temperature changes.

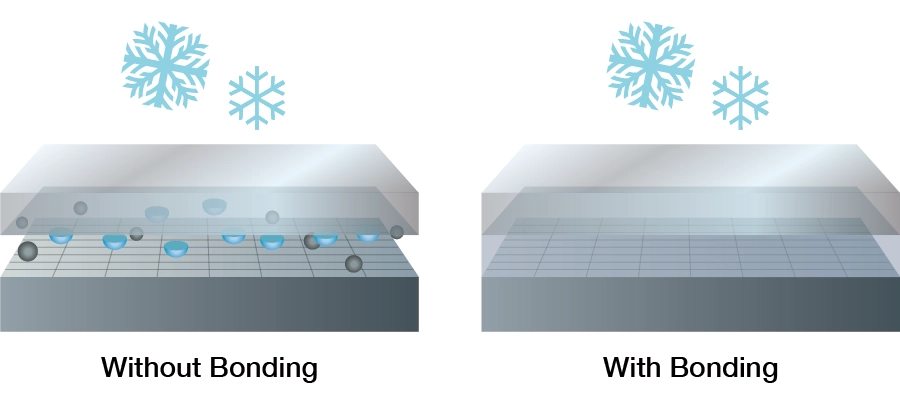

For touch monitors, the panel thickness influences touch accuracy and can affect usability with both touch pens and bare hands. A touch monitor with optical bonding maintains consistently accurate touch response making it easy to use and reliable.

Optical bonding is available for select models. Contact EIZO for more information.