Color Management Resources

Visit to the EIZO Headquarters - ColorEdge Factory Tour

Based in Tokyo, Japan, Mount Q provides of variety of video-related professional services and consulting to the film industry including DaVinci Resolve certified training, video technology seminars, YouTube live streaming support, software development, monitor calibration for the Mac environment, video editing, system design and installation, script writing, digital signage, DIT training, and server construction. Hisayuki Yamamoto, Technical Director at Mount Q, has been deeply involved in the workflows of video production, especially post production, since the age of 20. In 2023, he visited the ColorEdge production line at EIZO’s manufacturing headquarters in Ishikawa, Japan. In this article, he shares his impressions of the production line and his thoughts on EIZO’s commitment to quality products.

Entering the Factory for the First Time

I have long wanted to visit EIZO's head office and factory in Ishikawa Prefecture to see for myself how ColorEdge monitors are made, the philosophy behind these products, and the people who make them. I had the opportunity to visit EIZO and learn these things.

Since its introduction to the video industry in 1984, DaVinci Resolve has been by many producers to be the best color grading system available. To produce color in video with a high degree of accuracy, the color produced by DaVinci Resolve must be viewed through an accurate monitor. If the monitor is unreliable, our efforts to maximize our creativity are undermined.

This may be an old story, but during the winter break of my first year of high school, I worked part time for five days at a local calculator manufacturer’s factory. It was a small factory, but it had a line for making calculators, which were becoming popular at the time. Of course, I had no experience at all, so the tasks I was given with were surprisingly simple. The people who had worked there for many years were doing the assembly, which looked complicated. They were so used to it that they could hold a conversation with others while they were assembling.

This may be an old story, but during the winter break of my first year of high school, I worked part time for five days at a local calculator manufacturer’s factory. It was a small factory, but it had a line for making calculators, which were becoming popular at the time. Of course, I had no experience at all, so the tasks I was given with were surprisingly simple. The people who had worked there for many years were doing the assembly, which looked complicated. They were so used to it that they could hold a conversation with others while they were assembling.

Before entering EIZO’s factory, I had a preconceived notion that the atmosphere would be similar to what I had experienced in other places. It was intense when I walked through the doors of the production area for the first time. To use an analogy, it was like entering a martial arts dojo. As I walked through each production area, I soon understood my initial nervousness. It was the manufacturing manager, Mr. Tsuda, who guided me through the factory and explained in detail.

The people on the production line, as far as I could tell, ranged from their 20s to their 40s. Mr. Tsuda told me that the difference is not just in the number of years of service, but in the work each person can do, with skills depending on the level of difficulty. Starting at the beginner level, their skills gradually increase depending on which part of the product they are working on. Each skill is divided into nearly 40 parts, and each time one is completed, there is a certification system that reflects that level. Each person's certification was listed on a chart that was updated and posted on the wall. I felt that this system naturally increased motivation and goal satisfaction. I connected this system, which encourages the continuing development of individuals’ skills, with the serious atmosphere I felt at the site.

Production Line Design and Operation

This may be my personal opinion, but LCD monitors have a problem in displaying fast-moving video compared to CRT monitors of the past due to their different display method. Even if we use a monitor with a fast response time for video production, it is impossible to control the monitor, and its response time, on which content will ultimately be viewed by the general public. Given the current situation where LCD display devices have become the standard, I believe we must produce video with the assumption that there will be inadequacies in reproducibility for fast-moving content. So, if I were asked if a monitor with a fast response time is necessary for editing, my answer would be that there is no need to be that nervous. Even if we use a monitor with a fast response time for video production, it is impossible to control the monitor, and its response time, on which content will ultimately be viewed by the general public. Given the current situation where LCD display devices have become the standard, I believe we must produce video with the assumption that there will be inadequacies in reproducibility for fast-moving content. So, if I were asked if a monitor with a fast response time is necessary for editing, my answer would be that there is no need to be that nervous.Next to the production line was the department for production engineering. The engineers in this section are responsible for building the production line as well as maintaining and managing it during its operational phase. Because they are located next to the line, they are able to rush to the appropriate location immediately in the event of an unforeseen error in the manufacturing process. I was told that the majority of the production lines are designed by EIZO's in-house engineers. |

In order to accurately manufacture a large number of monitors, there are an extraordinary number of checkpoints, that use a combination of human eyes and mechanized systems to watch for defects. What was interesting to me was that they set a daily target number of products to be manufactured, and the system tracks the likelihood meeting that target every moment of the day. If they see a situation where they might miss the target, they immediately identify the cause and recover. That was my understanding, but there are sometimes cases where the number of products in process on the production line exceeds the target number. At first, I thought that if the number of products produced exceeded the target number, it would be considered a great achievement. I would certainly be happy about it. However, exceeding the target means that more energy is used in production than planned. Because of the social focus on energy procurement and consumption, it is not good to have too many units in process. For this reason, manufacturing is being managed with an awareness of how to get close to the 100% target without exceeding it. In order to accurately manufacture a large number of monitors, there are an extraordinary number of checkpoints, that use a combination of human eyes and mechanized systems to watch for defects. What was interesting to me was that they set a daily target number of products to be manufactured, and the system tracks the likelihood meeting that target every moment of the day. If they see a situation where they might miss the target, they immediately identify the cause and recover. That was my understanding, but there are sometimes cases where the number of products in process on the production line exceeds the target number. At first, I thought that if the number of products produced exceeded the target number, it would be considered a great achievement. I would certainly be happy about it. However, exceeding the target means that more energy is used in production than planned. Because of the social focus on energy procurement and consumption, it is not good to have too many units in process. For this reason, manufacturing is being managed with an awareness of how to get close to the 100% target without exceeding it. |

Measures to Improve Efficiency and Quality

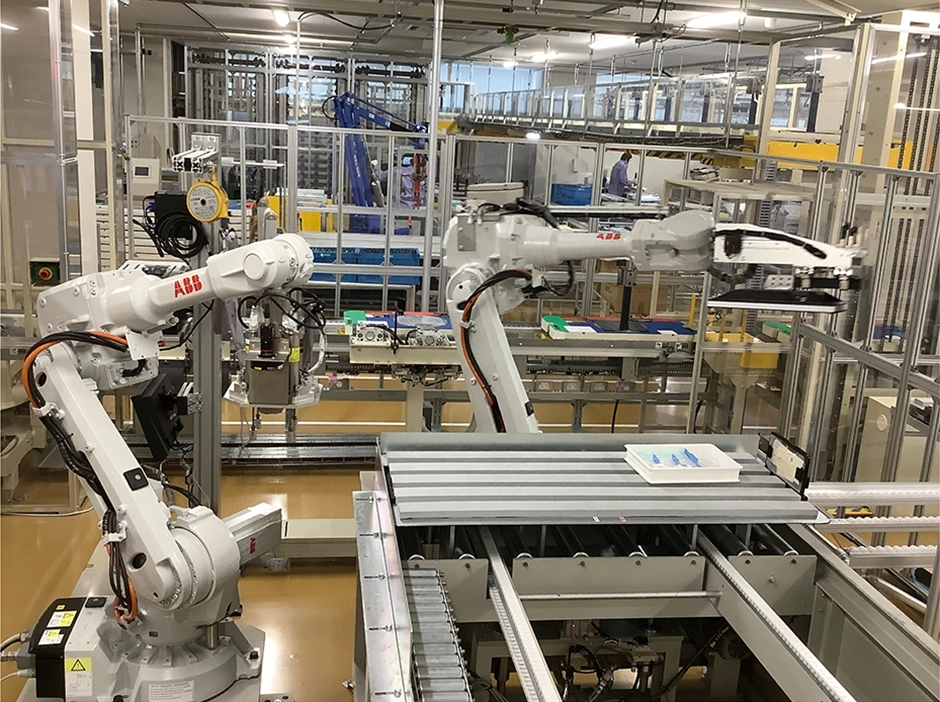

As mentioned earlier, the people working on the line have skills in the tasks they are responsible for. Although EIZO monitors are manufactured using their superior skills, they are not manufactured solely by human labor. Robotic arms are installed in some places in the line, and some parts of the process that used to be done by human labor have been partially replaced by automated processes. The development of such production lines will continue to accelerate in the future. I got the impression that the company makes a good distinction between tasks that can be more efficiently automated by robots or AI, such as heavy labor and adjustment work, and tasks that require assembly and inspection by skilled human hands.

In one corner of the line was an area enclosed by clear acrylic panels. There, a robot was attaching a stand to a monitor. But this stand was made entirely of metal. This is a special stand used during the LCD screen accuracy adjustment and post-assembly inspection processes. The special stand holds the monitor in place on the surface, ensuring a high degree of accuracy when measuring the backlit screen.

Robot for attaching metal stand |

Metal stand |

The next area had what looked like a series of cabinets, each large enough to hold a monitor. These were used for high-precision adjustment of each ColorEdge monitor. The monitors come to this location on the special stands mentioned earlier. Internally, they refer to this area as the “adjustment warehouse”. Each “cabinet” has a hole about 20 square centimeters in size. A calibration sensor that measures light automatically moves to each opening to perform measurement and adjustment. The cabinet-like arrangement allows dozens of monitors to be fit into multiple rows and columns. In the past, this process was done manually, which naturally took time and limited the number of monitors that could be produced in a day. Today, the process is fully automated, and when finished, the monitors are quickly transported to the next step.

A batch of monitors undergoes a process called “aging” to stabilize the display before the measurement. In the past, the aging time was longer, but as the accuracy of the parts used has improved, the time has been shortened, which has reduced the amount of electricity used, helping to reduce CO2 emissions.

All ColorEdge products undergo this aging and adjustment process before shipping. That's right, the adjustment report that comes with this product is created for each individual unit, and all units are also checked during the subsequent inspection process. In addition to the LCD surface inspection, PCs are installed throughout the line to record the manufacturing process. The PCs link the serial numbers of the products to each step of the process. So, if a user reports a problem after shipment, the serial number can be used to review each process to determine whether the problem occurred during manufacturing, or after shipment. In addition to identifying the source of the problem, the system is also useful for improving future manufacturing processes. Even if the same process is used for each product model, there are sometimes differences in the level of quality. Even in these cases, this system can be used to improve the manufacturing process by looking back at production history.

The Most Skillful Technique: Monitor Color Check

|

The process I most wanted to see during my tour of the production line was the color inspection of the LCD surface by human eyes. I saw a video on YouTube that showed how the human eye checks were performed on each unit. I was able to talk to the employee in charge of the visual inspection process, a young woman in her 20s, and she was kind enough to answer all my questions. She had earned many certifications in several of the aforementioned skills, had experience in many of the production processes, and was currently handling this color inspection process.  I also asked her if she is usually aware of screen quality when she sees monitors outside of the factory, and she said that she can’t help but notice the color quality and unevenness of other monitors. Understandable, considering that her work is entirely focused on the monitor screen. I also asked her if she is usually aware of screen quality when she sees monitors outside of the factory, and she said that she can’t help but notice the color quality and unevenness of other monitors. Understandable, considering that her work is entirely focused on the monitor screen.At this checkpoint, I was allowed to take my camera into the darkroom for a special photo shoot. Once inside, instead of the gentle smile from earlier, her expression changed as her eyes were sharp and focused. Her movements were nimble and each motion was made with purpose. Using her entire body, she studied every corner of the monitor screen, looking left and right, high and low. When she finished her inspection, she came out of the darkroom and her expression had returned to the gentle smile she had shown me earlier. |

|

|

On-Site Anechoic Chamber

The various departments involved in monitor manufacturing are all located on the premises of this main factory. Just as the production engineering department was located next to the production line, all the people involved in monitor manufacturing located on site and they can communicate with each other directly. In addition, the contact center that receives user inquiries, the support center that performs product maintenance, and the marketing department are also located on the same premises. I felt that this greatly contributed to the strength of EIZO’s products.

|

|

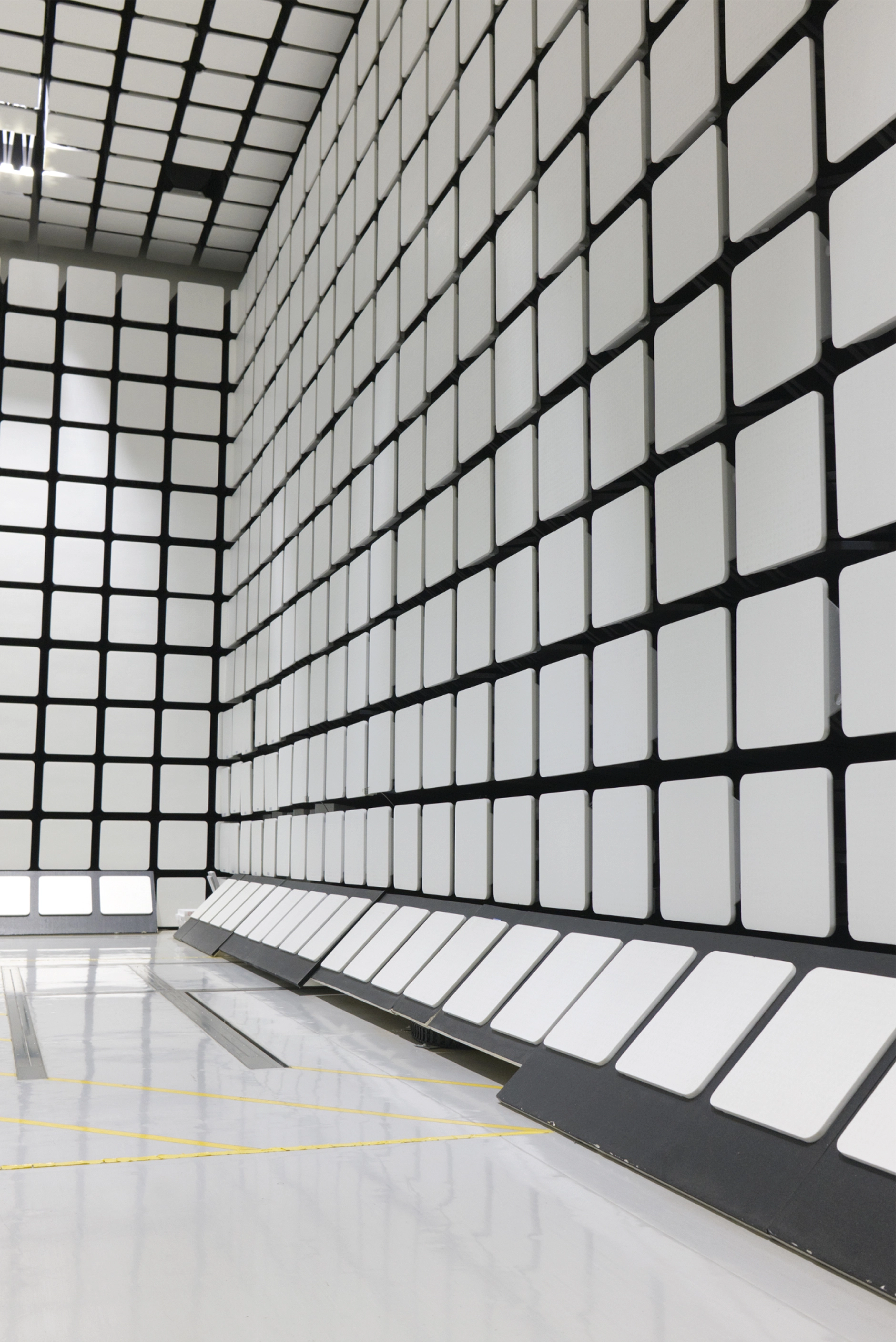

After visiting the production line, I was led to the anechoic chamber. Here, it was explained to me that monitors, as they are electrical devices with electronic components, emit some radio waves during operation. The anechoic chamber is used to measure these minute radio waves at the time of design, based on domestic and overseas standards. A darkroom is a completely dark place where no outside light can enter, such as when developing photographs. Similarly, in a radio wave anechoic chamber, all outside radio waves are blocked out. Generally speaking, not many manufacturers have their own anechoic chambers, and some outsource the measurement to other companies.

It was the first time I saw an anechoic chamber, and like a soundproof room, the walls were made of a foam material to absorb radio waves. Antennas for receiving radio waves are positioned toward the location where the equipment is installed, and they are said to receive radio waves emitted from the products at various angles without any leakage. By having their own anechoic chamber, they have the advantage of being able to repeat measurements repeatedly, even if the measurement time is long.

Interview with ColorEdge Engineers

|

After the factory tour, I had the opportunity to speak directly with five key engineers involved with ColorEdge. Starting with the person in charge of the production line we saw earlier, the person in charge of the production line itself in the production engineering department. In addition, we had the people in charge of software and firmware, as well as the head of ColorEdge development. We discussed the ColorEdge production process, how ColorEdge monitors achieve consistent color, and the philosophy behind these monitors. I was able to hear many stories about ColorEdge, including some of the many challenges the team had to overcome that I had never really thought about before. Now I really understand the reason I feel so confident with ColorEdge. |

|

Behind the Scenes of ColorEdge – Special Movie

Mr. Yamamoto made a special movie about EIZO's manufacturing processes that he experienced during the factory tour.

|

About the Author |

Hisayuki Yamamoto, Technical Director of Photography / Lecturer, Department of Photography, Nihon University College of Art

Hisayuki Yamamoto, Technical Director of Photography / Lecturer, Department of Photography, Nihon University College of Art