Color Management Resources

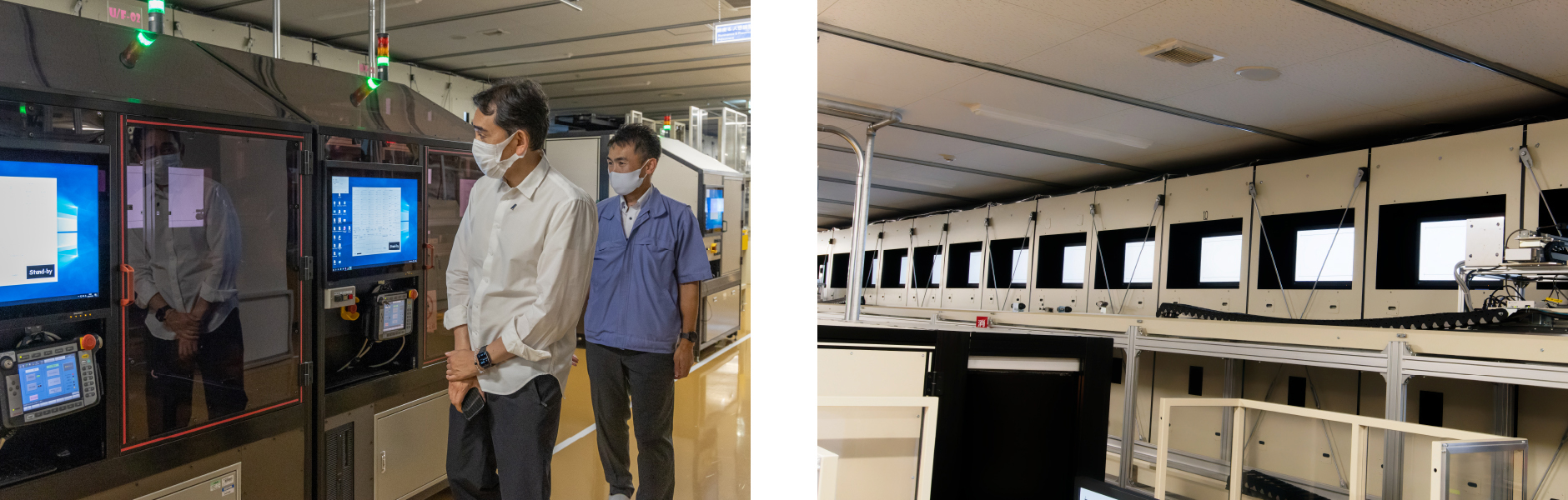

A Professional Photographer's Visit to the EIZO Factory

ColorEdge Ambassador Nagayuki Kojima gets up close and personal with EIZO’s headquarters.

Nagayuki Kojima, who has been a ColorEdge Ambassador since 2021, is a photographer who has expanded his activities around the world while engaging in studio photography in his hometown of Mima City, Tokushima Prefecture. Mr. Kojima visited EIZO headquarters to see the where monitors are made in person and to talk with the developers of the new ColorEdge CG2700X and CG2700S.

More about the ColorEdge Ambassador Program

|

|

|

About Nagayuki Kojima At the age of 30, he started taking photographs to record his children growing up, and at the age of 40, he left his job and established his photo studio Photo Art Kojima. Recently, he has taken on the challenge of international wedding/portrait photography competitions, and more than 200 of his photographs have been selected for competition. Mr. Kojima is also highly regarded for his development work and is commissioned by photographers around the world to assist them in retouching and printing their work. Mr. Kojima is using ColorEdge CS2740 in his photo studio in a multi-monitor configuration. In this case study, he talks about what he considers important in the creating his work and how he feels about using ColorEdge. |

|

|

EIZO's headquarters, located in Hakusan City, Ishikawa, Japan, handles all aspects of the product life cycle including product planning, development, quality assurance, manufacturing, and after-sales support. EIZO uses this in-house integrated approach to deliver high-quality products to users worldwide. Monitors that are shipped domestically and internationally are produced daily at EIZO's factory headquarters. During his visit to the head office, Mr. Kojima was able to see how the ColorEdge products that he uses everyday are manufactured. |

EIZO Manufacturing Headquarters, Japan |

|

Production Process |

Assembly Area |

|

Aging and Adjustment |

|

Overseeing Manufacturing Progress |

Final Inspection |

Comments from Mr. Kojima

The factory tour lived up to my expectations. It was a moving experience. The spirit of craftsmanship is everywhere, and the monitors are produced efficiently using the various systems developed in-house by EIZO. In addition, the diligence and professionalism of the people working there made me realize how important it is to be able to trust a company. As the tour progressed, I found myself becoming an even bigger fan of EIZO monitors. Once again, I would like to thank everyone at the head office and factory for allowing me to visit despite the restrictions related to Covid-19.

![]()

A Conversation with the Developers of ColorEdge

Mr. Kojima, who has been using ColorEdge for many years, spoke with the developers of the new ColorEdge CG2700X and CG2700S about EIZO’s manufacturing process and the starting point of Mr. Kojima’s career as a photographer.

Left to right: Koichi Okumura in charge of model design, Takao Maekawa in charge of application development, ColorEdge Ambassador Nagayuki Kojima, and Takahiro Kono in charge of hardware development.

Attention to Detail in Photography

The Importance in Having the Right Environment

About the New CG2700X / CG2700S

Built-In Calibration Sensor

Making a Product for Everyone

ColorEdge in the Future

Reasons for Becoming a Photographer

Kono: So, what made you become a photographer, Mr. Kojima?

Kojima: When I was 30 years old and married, we had our first child. So, I started to record the growth of my child. Of course, I was using film at the time.

I wanted to take the most beautiful pictures I could to leave with them, so I decided to learn how to take better pictures. I entered a photo contest for a local newspaper, which went well and I won many times. However, after a while, I became overly conscious of winning, which became stressful. So I gave up of photography for a while and only kept a camera for capturing life events, such as my child’s sports events.

About three years after I left photography, I went skiing. I happened to have my camera with me and took pictures of my friends skiing. I printed them out and gave them to my friends, who were very happy. Then I thought, “This is what photography is all about! If it makes even one person is happy, it's worth it.” And that's when I got back into photography.

It was then that I bought a Canon digital camera and realized the evolution of digital. With that as a starting point, I made a complete shift to digital. I started taking pictures again and photographed the wedding of a friend's son. Through word-of-mouth, other people were asking me to shoot their weddings, and when I was 40 years old, I decided to leave my day job to make a living from photography. That was the beginning of my career.

Attention to Detail in Photography

Kono: I have seen some of your work, and the way you frame a subject is quite unique. It gives the impression that there are several layers within the picture.

Kojima: I never really thought about it, but I do like architecture very much. I am very interested in architecture as an art form, and that may have influenced me somewhat.

Kono: Do you take pictures while measuring exposure?

Kojima: I have only ever used spot metering since my days with film. I used manual metering, but never any of the camera's auto functions. In the film era, I used reversal film, which was quite expensive. And since developing film was also expensive, I never wanted to make a mistake with the shutter. So, I always used spot metering to get the correct exposure. It is the same for me today, even with digital cameras.

Kono: With spot metering, won’t some parts of the image be more saturated from others?

Kojima: It's actually a good thing. I don't want to miss out on the highlights, so I measure the exposure of the highlights and create the shadows.

The Importance in Having the Right Environment

Kojima: I think ColorEdge monitors are used by people in a wide range of fields, but not always in the right working environment. What are your thoughts on this?

Kono: We want our products to be used in an appropriate environment, such as an environment that is not exposed to outside light, or in an ambient light environment with high color rendering lighting, so that colors do not shift.

Kojima: If the entire photographic industry were more sophisticated, I think the problem of color mismatch would disappear. I think this is something we should continue to work towards.

Also, when people ask me what monitors I recommend, I tell them that many album makers and developers use ColorEdge monitors because they are more likely to see consistent colors.

Kono: Ensuring perfect color communication without everyone in the production workflow having the same understanding of monitors and display modes is a challenge. Monitors also need to be adjusted to the same standards.

About the New CG2700X / CG2700S

Kojima: What are the new features and highlights of the new CG2700X / CG2700S?

Kono: The part I am most happy about is, of course, the image quality. For the past two or three years, parts have not been coming in as expected because of Covid-19, and we had to work very hard to make this model, so I am very attached to it.

This model has improved functionality with its USB Type-C connectivity. Recently, as the production environment has shifted from desktop to notebook PCs, a single USB Type-C cable can be used to display video, transmit USB signals, and supply power to a device. In addition, the multiple USB ports allow the monitor to act as a docking station by connecting a mouse and keyboard to the monitor instead of the PC. And for the first time in the ColorEdge lineup, the monitor is equipped with a LAN port, enabling a stable network environment by simply connecting the PC and monitor with a single USB Type-C cable.

The most significant feature is the increased power capacity that can be supplied to the PC via USB Type-C. Previously, ColorEdge monitors equipped with USB Type-C could deliver up to 60W of power, but the CG2700X and CG2700S can now supply up to 94W and 92W, respectively. However, this increased power supply capacity naturally causes heat to build up inside a monitor. Heat buildup affects the quality of the display, so typically a fan must be installed to dissipate the heat. However, fans can be noisy and annoying to the user. In order to achieve both heat dissipation and noiselessness, we took great pains to design it to be fanless. Through trial and error, we arrived at a new design for the monitor housing.

Kojima: So that's what the punched metal on the back of this monitor is for. I thought that it looked pretty cool. My CS2740 supports power delivery of up to 60W, but the CG2700X / CG2700S exceeds that with over 90W for more demanding workstations.

Kono: We needed to drill holes in the housing to allow heat to dissipate, but the challenge was to make it attractive.

Kojima: I'm not sure many users pay much attention to the back of the monitor, but it shows your dedication.

Okumura: In most cases, TVs are placed against a wall so you can’t see the back, but with monitors, the back is often visible, so we are very particular about how the back is designed. We first considered a plastic exterior, but it looked bad, so we came up with the idea of using punched metal, which allowed us to create small holes to dissipate heat. We conducted numerous simulations to determine the appropriate size, number, and area of the holes before developing the prototype.

Kojima: Is there anything that has changed with regard to display performance?

Kono: The new models inherit the high performance and functions of previous ColorEdge monitors in terms of display quality. For the past 20 years, ColorEdge has continued to evolve in response to customer requests, so there is only so far forward we can go in terms of fundamental display quality. The challenge is to maintain this standard of performance in the next generation of monitors.

Kojima: I see! Do you mean that, contrary to conventional products, it is difficult to maintain panels and boards at the same level of quality?

Kono: Yes, that's right. Each product uses a different panel and has different characteristics. It is actually quite a hurdle to make a product with the same level of quality as another.

Kojima: Why don't you develop and produce the panels in-house as well?

Kono: We produce not only the ColorEdge but also many other monitors with different functions and performance requirements, such as monitors for business, medical, and industrial applications, so it is not realistic for us to produce panels for all applications in-house. It is difficult to do so considering the cost of maintaining a factory to produce all those panels. One advantage of not making our own panels is that we can choose the best panel for each application at any given time.

Kojima: I’d be upset if you made a ColorEdge that costs 1 million yen or something like that (laughs).

Kono: We will continue to work with panel manufacturers to adopt panels that can deliver the required performance.

Built-In Calibration Sensor

Kojima: I wanted to ask this for a while. I have been using the i1 Pro series sensor for many years, and I am currently use the CS2740 monitor, which is not equipped with a sensor. The sensor built into the CG series is a filter type, but how is its measurement accuracy compared to spectrophotometers such as the i1 Pro series?

Kono: The sensor built into the ColorEdge CG series is made of materials that are carefully selected to prevent color shift, etc. We use only materials that we have confirmed do not shift while conducting storage tests.

Kojima: I was told by the manufacturer that the sensors had a use-by date of 3 to 5 years due to filter degradation, depending on the environment. What about the ColorEdge's built-in sensor? Does that mean that we can ignore the degradation over time?

Kono: That's right. We believe that the sensor itself is the measure, so we select sensor materials based on the idea that we cannot use a sensor whose measure is off. We provide a standard 5-year warranty on our products, and the sensor is included in that warranty. However, it does not mean that the sensor will not change over time, so please keep this in mind.

Learn more about the award here.

Maekawa: ColorNavigator has a correlation function. It allows the characteristics of the measurement values of the built-in sensor to be matched with other sensors. When we first started using the built-in sensor in ColorEdge, the amount of change over time was greater than that of the current sensor, and many people told us that the color would change quickly because it was a filter-type sensor.

Especially in the film industry, there were many opinions that people wanted to use the system in according to the characteristics of a reference sensor. For example, since there is not a lot of variation over a six-month period or so, we made it so that the ColorEdge built-in sensor could memorize the characteristics of the reference sensor, perform automatic calibration regularly for half a year, and then correlate to the reference sensor again after that. This allowed us to mitigate changes over time and make the process more efficient for customers. In addition, the built-in sensors of the CG series are calibrated to the characteristics of industrial-level measuring instruments such as the CA-410 and CS2000 before shipment from the factory for precision right out of the box.

Kono: Have you ever had any difficulties with misaligned sensor readings?

Kojima: Yes, I have. One day, when I calibrated the monitor, the gray was quite reddish, and when I calibrated it again, it displayed the same as usual, and I wondered why. One of your developers discovered that the problem occurred when using ColorNavigator with certain sensors. I replaced the sensor with a new one, and I haven’t had any problems since.

It’s frustrating when you don't know the cause of an issue. In another case, my calibration results were strange, so I sent the sensor to be checked, but it did not improve. In the end, changing the USB cable solved the problem.

Kono: There can be isolated problems when using ColorEdge and external sensors. The decision to build the sensor into the monitor was also based on the sporadic problems with an external sensor. In many cases, completely different situations would cause the same color shift. We’ve seen cases where a professional, high-end sensor was used and the colors did not match, and cases where a comparatively inexpensive sensor was used and the colors did not match. We were troubled by this problem, so we decided to incorporate a sensor that had been thoroughly adjusted at the factory and automatically calibrated over a certain period of time to maintain stable quality - and the ColorEdge with built-in sensor was born.

Kojima: In fact, I know of some people who use an external sensor, but purchased a CG Series monitor with a built-in sensor and they say that it is very good because it automatically calibrates itself when they are not working, so they do not have to worry about it.

Kono: We develop monitors based on the concept of minimizing hassle so users can focus on creating. Calibration is necessary to keep the screen accurate, but we hope to alleviate workload as much as possible by incorporating a built-in sensor.

Kojima: I know that many people use not only PCs and monitors but also other peripheral devices in close proximity to them. Is there anything to keep in mind with regards to that?

Kono: As for whether external devices will affect with the quality of the panels, there is no need to worry because we have conducted tests to confirm such environments.

Making a Product for Everyone

Okumura: I am in charge of all design-related aspects of EIZO products. I work with outside design companies to create UI for software and applications, including product design. I am in charge of products for various fields, but I am particularly enthusiastic about ColorEdge because it is a product used by creators.

Kojima: I have heard users say that the new ColorNavigator 7 calibration software for ColorEdge is more difficult to use than it used to be. Some users find it difficult to use not only because of the software functions, but also because the UI has changed, so the design is difficult in this regard.

Okumura: We strive every day to create products that are easy for everyone to use despite various limitations, but it will always be difficult to create something that is acceptable to everyone.

Kojima: If the UI doesn't change, anyone should be able to use it. That would be ideal.

Okumura: It would be nice if there were a universal platform, so users could use it easily.

Kojima: Having said that, the people who use the software can speak their minds without hesitation, but that pushes the people who make it in a corner (laughs).

Kono: We developed the new ColorNavigator 7 after considering how we could take an approach that is easy to understand for all users, given that each user has a different way of using the software - photographers, designers, and filmmakers. On the other hand, for users who were familiar with the previous software, the change in UI design may have confused them.

Maekawa: I understand all too well what users said early on about how difficult it was to use. ColorNavigator 7 combines the functions of two previous software applications, ColorNavigator 6 and ColorNavigator NX, and their functions into one. So we had no choice but to change the UI. For existing users, the new software was inevitably difficult to use until they got used to the new UI. However, rather than provide two software applications with different functionality, we thought it would be better in the long-run to create a single software solution with all the features of both. Although it was a difficult decision, this is how we developed ColorNavigator 7.

ColorEdge in the Future

Kojima: Is there any product that you would like to make in the future?

Kono: When I joined the company, I wanted to create products that would make users happy. As for me personally, I want to create products that help create an environment in which people work creatively.

Maekawa: ColorEdge is promoted as a monitor that can be hardware calibrated, but I don't think people buy it because they want to calibrate it. If color reproduction could be maintained accurately without calibration, that would be ideal. We believe that the ultimate goal of ColorEdge is to produce colors as expected without needing calibration - just by buying the monitor and using it as is.

We want to reduce the number of times calibration is required, and to reduce the number of steps, even if it’s just one or two, so that the software can be used without the user having to think too hard about it. Our goal is to create software that maintains accurate color display, but does not require the user to do any extra work to achieve it.

Kojima: It would be nice if you could approach this idea with software. Even if software is available, some people never adjust their monitors after they buy them. Some people try to adjust the monitor but they don't know how to do it. For example, if you want to print a photo, it is normal to use a color temperature of 5000K, but there are surprisingly few people who use 5000K. I wish there was a way to let people know these things more clearly.

Maekawa: Yes, that's true. The increase in the number of calibration targets has increased the number of choices on the UI side, and I think that makes people wonder which one to choose.

Kojima: There are a lot of people who buy a good monitor and think that it will stay the same as when they bought it. I’ve also heard people say that the color display of the latest notebook PCs is wonderful because it matches the colors of their prints without any adjustment to the screen, but I have a hard time believing that.

Maekawa: It would be great if we could make something that automatically adjusts the display state for people who are not as familiar with color management.

Kojima: The industry itself needs to progress.

Maekawa: Sometimes we do not provide enough information, or its inconvenient to look it up on the website, or it is not clearly explained. We need to develop a UI that can convey this information well on the software.

Kojima: It would be very easy to use the software if it automatically adjusts to the most appropriate display mode simply by answering a few questions on the software, such as “Are you a photographer?”

Maekawa: That is a good idea! Although there is nothing better than being an expert in color management, we want to create an environment that allows our clients to concentrate on their core creative focus.

Okumura: In the course of my involvement in design, I am often asked what “design” is. My answer is always the same: It is something that brings joy to people. That is what I believe.

Kojima: I also answer the question, “What is art?” with “It is something created to bring joy to other people.” We are similar. I came up with that answer while studying history.

Okumura: A well-designed product feels good to use and makes people happy even if they don't know why. I think that people continue to use it, they will be enriched by the little things along the way.

That is why I would like to continue making products that are designed with the user in mind, and that will enrich their experience, even if just a little, rather than something very flashy.

![]()

Interview with Nagayuki Kojima

![]()