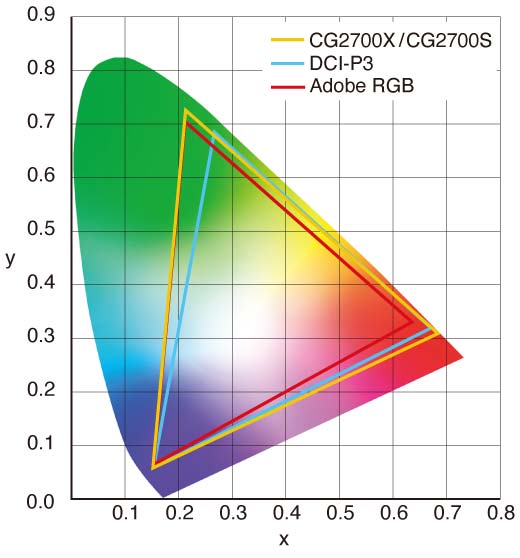

Faithfully Display Colors to Industry Standards

Textile digital workflows must ensure that designs are accurately represented from the initial concept to the final product. The wide color gamut of ColorEdge monitors fully covers the sRGB and almost all of the Adobe RGB* color spaces, enabling compatibility and color consistency throughout design, print, and quality control processes. Additionally, the CG series covers almost the entire DCI-P3 standard for exceptionally faithful color reproduction. Work with confidence knowing that colors can be displayed accurately across digital swatches and samples, textile batches, fabric simulations, and prototypes.

*Excludes CS2400R