Industry

EIZO Manufacturing Headquarters - Maintaining Visibility in the Factory

EIZO Installs Its Own IP Decoding Solutions to Maintain Visibility of Production Processes

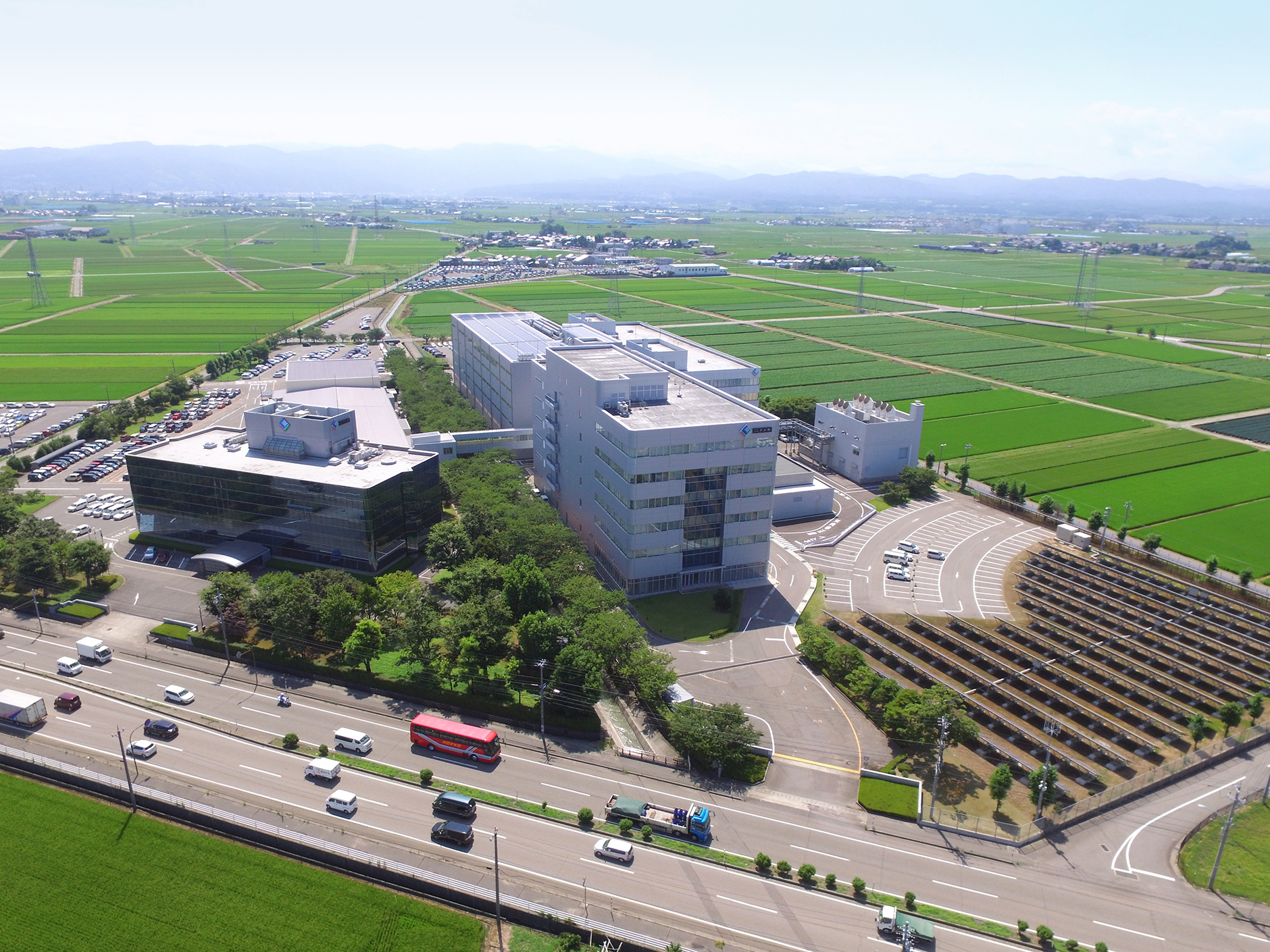

| EIZO headquarters in Hakusan, Ishikawa Prefecture, Japan, is home to the planning, development, quality control, manufacturing, and after-sales support processes for its various product lines. It is this unique integrated production that enables EIZO to bring high-quality solutions to users around the world. At the factory, where LCD monitors and visual solutions are manufactured, EIZO has installed its very own IP decoding monitor and box solutions that are connected to IP cameras for keeping eyes on production processes and ensuring employee safety. Introducing these solutions now allows EIZO to maintain visibility of the production floor in real time, which provides many benefits as a result. |

EIZO headquarters in Japan where the factory is located |

Index

Challenge 1: Lack of Visibility in Restricted Entry Clean RoomChallenge 2: Difficulty of Tracking Operation Status and Unmanned Production Processes

EIZO IP Solution Features

Challenge 3: Difficulty for Supervisors to Check Process Progress

Deployed Products

Challenge 1

Lack of Visibility in the Restricted Entry Clean Room

Easy to Check the Safety of Workers Remotely

Clean room from the outside |

Operations inside the clean room |

EIZO's factory has its own ISO Class 1* clean room where touch panel monitors and other sensitive products are produced. Class 1 is the highest classification of ISO 14644-1. In order to maintain the strict standard for cleanliness, only a small number of workers are permitted in this area. This restricted entry made it difficult for supervisors outside of the clean room to monitor progress and check on the safety of the staff inside. That is where the DuraVision FDF4627W-IP comes in - this large 46-inch IP decoding monitor was installed in the management office which enabled supervisors to check on progress and monitor worker safety from outside the clean room.

* ISO 14644-1 Class 1 specifies a maximum concentration of particles of 0.1 micrometers per 1 m3 of air.

46-inch IP decoding monitor installed in the management office for production control |

Employee Voice

|

Challenge 2

Difficulty of Tracking Operation Status and Unmanned Production Processes

Increased Visibility of Unmanned Process for Efficient Use of Labor and Safe Operation

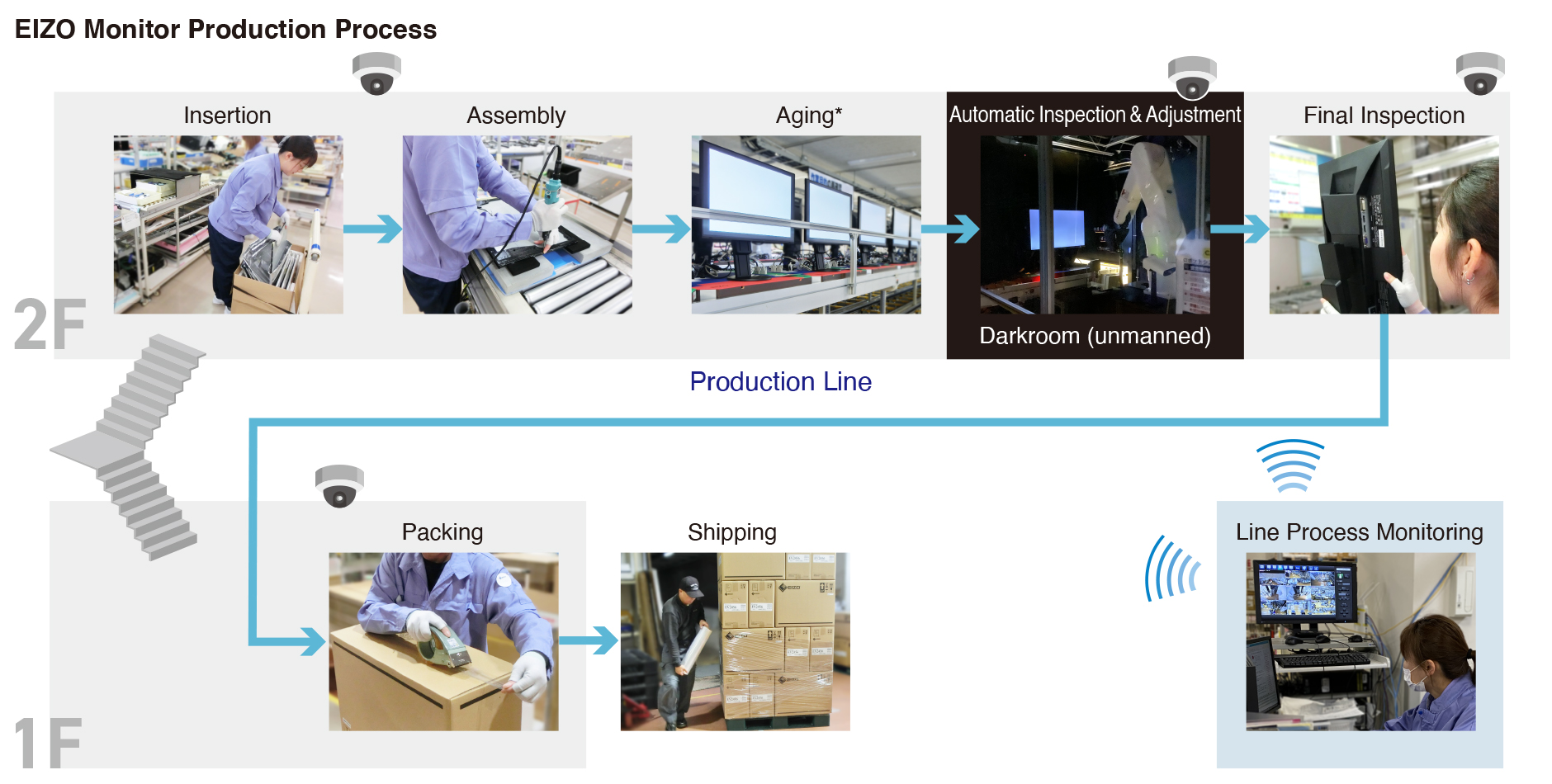

EIZO has been working towards digital transformation (DX), having adopted its own automatic inspection system that uses artificial intelligence (AI) in the monitor production process.

*A process where the monitor is left on for an extended period to confirm stability.

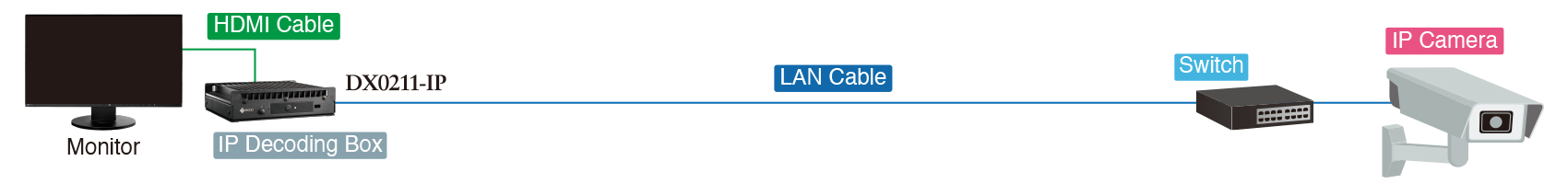

Since the inspection process is conducted in an unmanned darkroom, production staff are not able to go inside and watch over the process at all times. To solve this, EIZO installed an IP camera inside the inspection room that is connected to the IP decoding box DX0211-IP and 31.5-inch 4K monitor mounted on the wall outside the room. With just a LAN cable between the camera and the IP box, the monitor displays images from inside the inspection room from over the network. This has allowed EIZO to detect and address abnormalities early and reliably maintain smooth operations.

|

|

| Large-screen monitor enables visibility of the unmanned inspection room | |

EIZO IP Solution Features

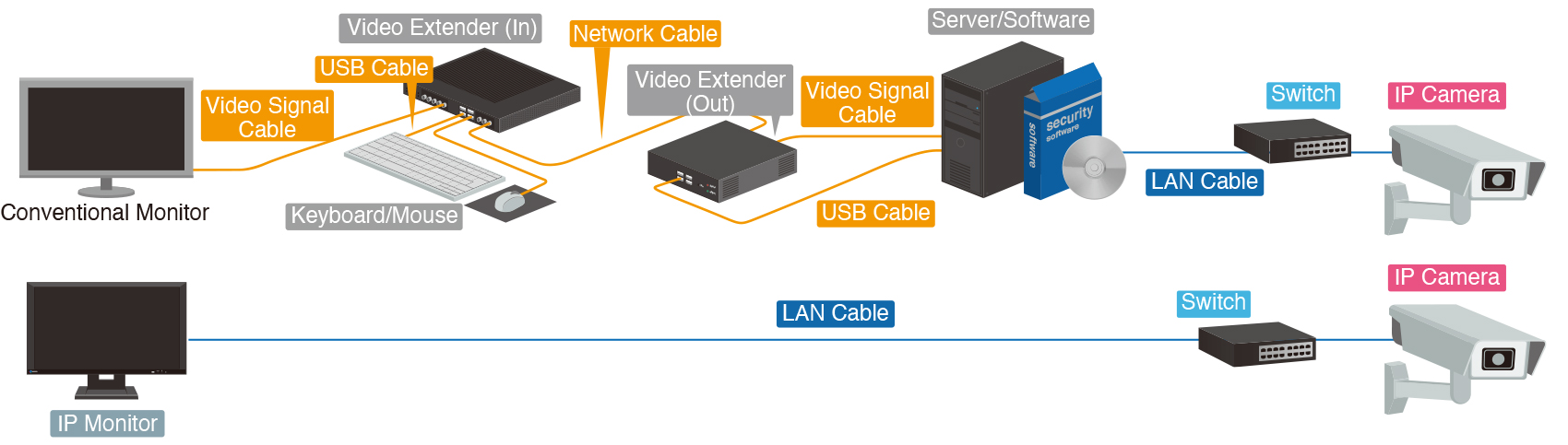

1) Monitor with Integrated Decoder

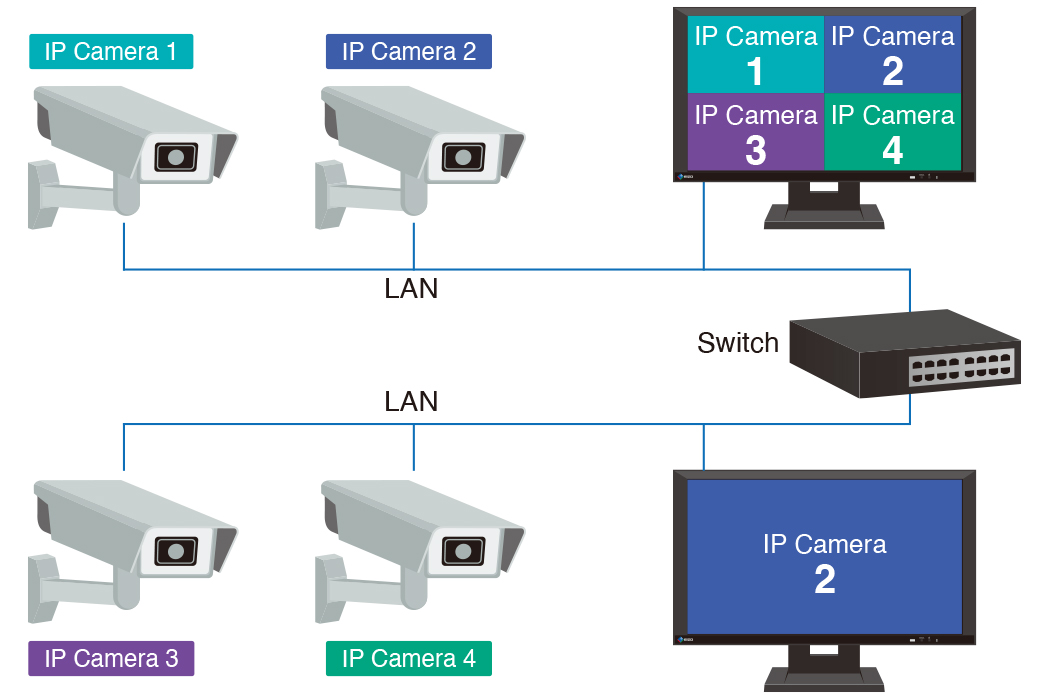

EIZO IP decoding monitors are equipped with an IP decoder, which allows the monitor to connect directly to an IP camera using only a LAN cable and switch. They can display up to 16 or 32* feeds simultaneously on a single screen and can be flexibly installed on wall mount for saving space.

*Varies by model

2) Box Solution for Combining with Any Size Monitor

The DX0211-IP is a compact IP decoding box that brings the same functions of the IP decoding monitor to an external box format. This allows users to combine it with any monitor size to suit their installation needs.

The DX0211-IP can also be mounted directly on the back of a monitor, as is the case at EIZO’s factory, keeping the installation area neat and saving space.

3) Simple to Add Monitors to the Infrastructure

Since multiple monitors can be installed on the same network, it makes it easy to keep eyes on multiple locations. The IP decoding monitor and box offer simple connection to a network switch via LAN, so new devices can easily be added in future installations.

Manager Voice

|

Challenge 3

Difficulty for Supervisors to Check Process Progress

More Efficient View of Production Processes

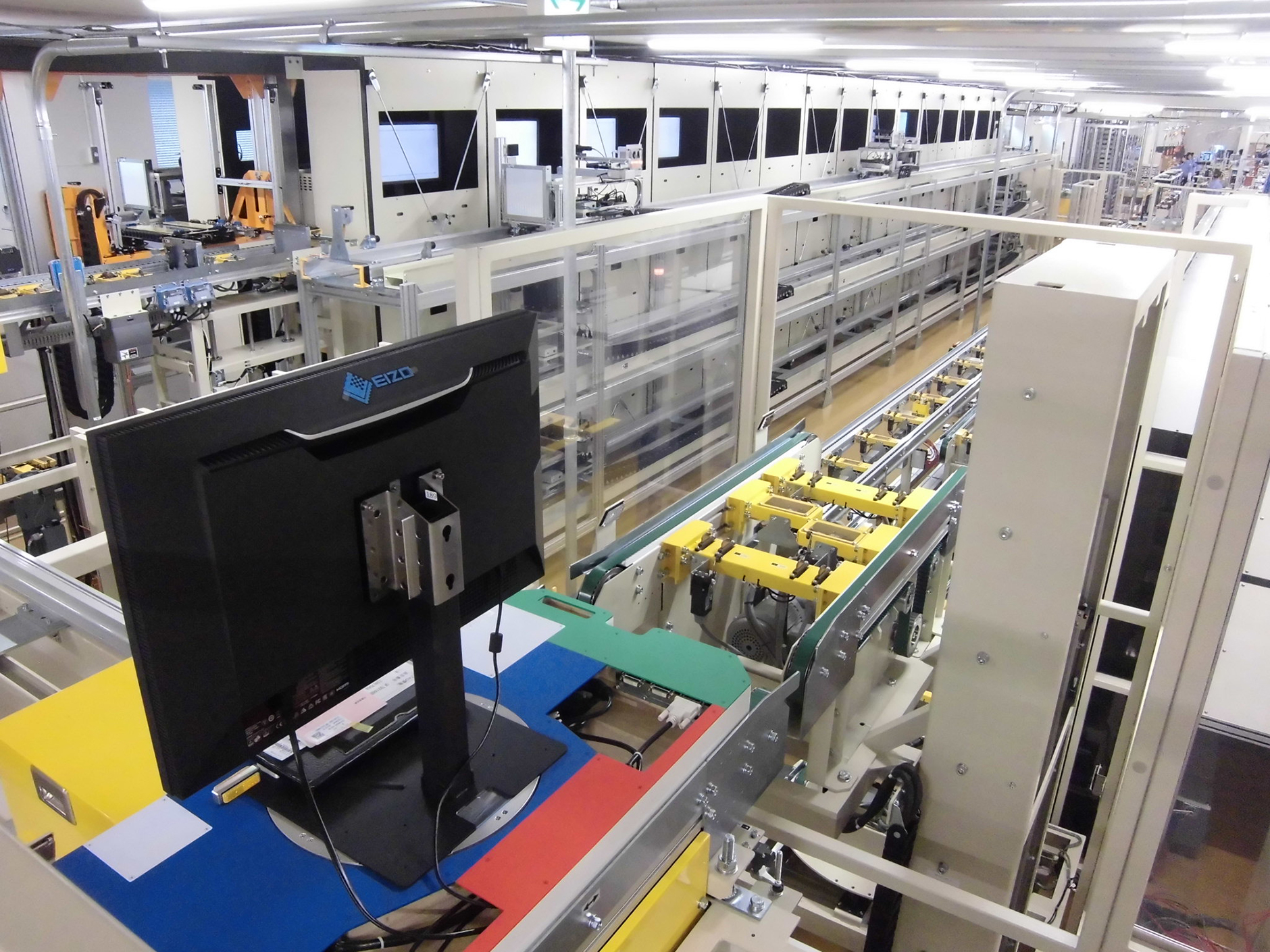

The latest additions to EIZO's factory line are automated processes which use AI to save on labor. Since they are usually unmanned, IP decoding monitors are installed at the work areas which directly follow these processes in the production line, where staff conduct visual inspection of products. In addition, since the assembly, inspection, and packaging processes are conducted across multiple floors, this allows production staff to easily check the progress of the previous process, make appropriate personnel adjustments, and effectively manage the backlog, all of which leads to improved production efficiency.

State-of-the-art automated production process |

Confirmation of the automatic processes while production continues |

Checking the production line on another floor via the monitor |

Deployed Products

- DuraVision FDF4627W-IP

- DuraVision FDF2304W-IP (Successor Model: FDF2312W-IP)

- DuraVision DX0211-IP(Successor Model: DX0212-IP)