Sustainability

Corporate Culture

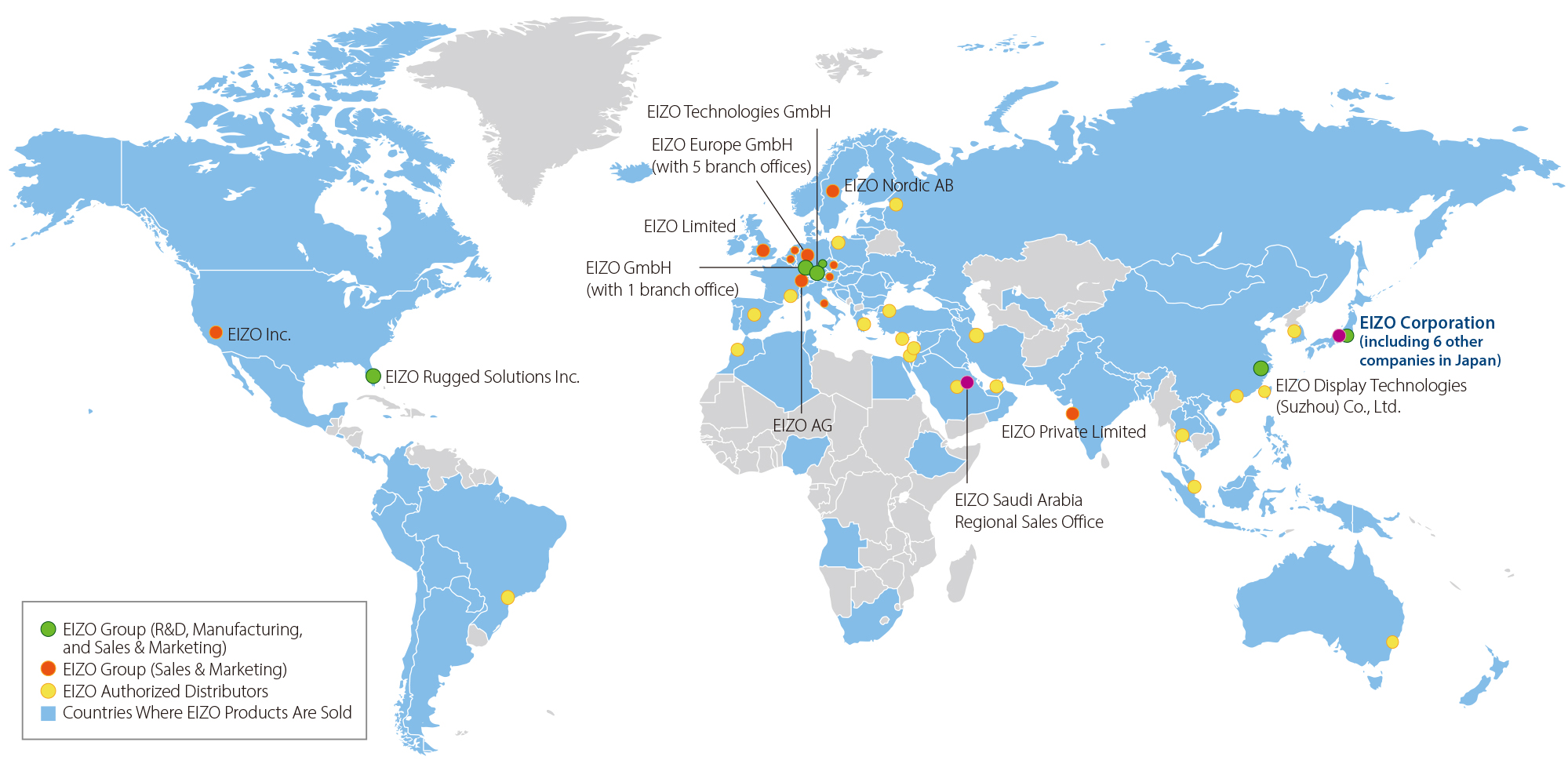

While respecting the human rights and promoting a mutual understanding of different cultures, our Group companies and distributors in various countries maintain strong mutual relationships to support customers worldwide.

People are the key to supporting the EIZO brand. Upholding our free and open corporate culture, we constantly work to create an environment in which each employee can demonstrate their abilities and thrive.

Business with a Global Outlook and Mindset

EIZO products are sold in more than 100 countries and regions worldwide by a network of Group companies and distributors.

Sales Network

From the very beginning of selling proprietary products outside Japan, we have adopted a one country/territory, one distributor system, in which a single distributor (or Group company) is responsible for all sales within a given country or territory. This unique system enables us to accurately discern customer needs in each country or territory by distributors or Group companies that fully understand the culture and values of their respective regions and provide optimal products. It also allows us to offer products through sales methods that are appropriate for each country or territory.

However, custmers in specific market such as healthcare, graphics and V&S (Vertical & Specific) demand direct, ongoing communication with the manufacturer as well as solid global support. To effectively respond to these specific market environments and diversified sales channels, we have sales subsidiaries in the United States, United Kingdom, Germany, Switzerland and Sweden. We strive to achieve further business growth in Europe by reinforcing regional sales in North America and Europe. Furthermore, to expand our sales activities into emerging markets, where our specialized markets are expected to grow, we have employed local sales staff in Saudi Arabia, the U.A.E. and India and are enhancing our approach to customers.

100% In-house Development & Production

The EIZO Group has three production sites in Japan, Germany, the United States and China, forming a network that maintains a coherent development and production system throughout the Group. This enables us to apply stringent quality control from development to production, promote the creation of development synergies that maximize the strengths of each base, and construct an optimal production system for each market and customer. In addition, we promptly share information obtained in the course of development and production along with opinions and requests obtained from markets and customers to incorporate into product development and customer support.

Human Resource Development Initiatives

Human Resource Development Policy

We aim to propose products, systems, and solutions that exceed our customers' expectations based on our strength in various customizations to meet their needs, with imaging technology at the core. We have formulated a medium-term human resource development policy, "We will develop human resources with more flexible thinking and practical skills to respond to the age of VUCA, based on the development of diverse human resources who can 'create' and 'support' the next business model amid the increasing sophistication and complexity of manufacturing. This is our medium-term human resources development policy.

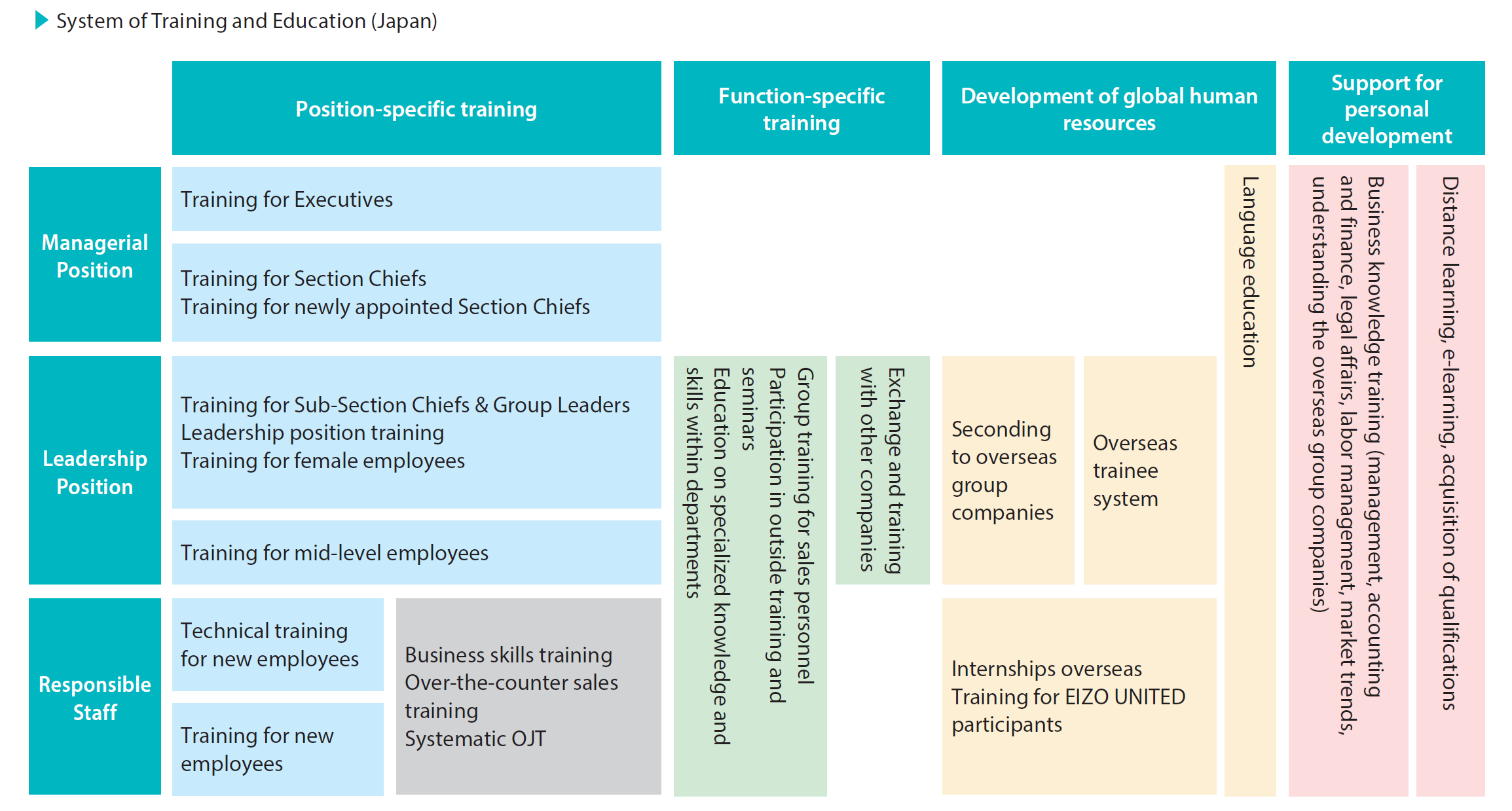

Enhancement of education and training

To develop a diverse range of human resources to supportour business, we plan and implement a variety of training and education programs in Japan, including training by job level and function, global human resource development, and assistance for self-development while keeping abreast of internal education and training needs. In our overseas group companies, we organize training opportunities for the entire company and individuals for developing the respective skills required by product development and sales operations. Moreover, we seek to raise skills by making use of on-the-job training and external seminars.

Personnel Exchange within the Group

We encourage personnel exchanges within our group companies in which young engineers are dispatched for shortterm or long-term training. These programs are intended to increase the number of employees who can work effectively in different cultures and manage technology from a global perspective as well as to cultivate new technological expertise.

Cultivating the EIZO Mindset

We are working to nurture and sharing the "EIZO mindset" of creating the "world’s best" to unite EIZO in creating and delivering stateof-the-art products and services to customers globally.

EIZO UnitedAround 100 participants from Group Companies and EIZO Authorized Distributors gather once a year at EIZO Corporation (Japan) to attend the "EIZO United" conference, where we share our latest technologies, the status of sales in each country, various initiatives and the overall product and business direction. Not only does this deepen everyone’s understanding of our future direction, it fosters a strong sense of unity in the group through mutual exchanges. This also provides opportunities for employees in various departments to present their department’s initiatives to cultivate a sense of belonging to "One EIZO." |

|

Global MeetingsWe carry out a variety of meetings across EIZO every year. These include global meetings for raising the level of quality control throughout EIZO, a EURO Meeting for discussing sales strategies within EIZO (in Europe), and other business unit meetings. |

|

Joint Participation in Trade ShowsEIZO participation in international trade shows includes staff from the exhibiting company as well as from other group companies to share market information and conduct coordinated global sales and development activities. |

|