Monitor Basics in Plain English

The Making of a FlexScan Monitor

- Security

- ATC Resources

- Monitor Basics in Plain English

- Integrated Production – Made in Japan

- Expert Advice – The Best Way to Invest in Your Home Office

- FlexScan EV2795: A Writer’s Extensive Review

- Efficient Telecommuting with a Laptop and Monitor

- What is the Optimal Display for Watching Video? – The OLED Revolution

- Integrated R&D, QC, and Production

- Adding a Touch of White

- HiDPI

- What We Discovered After Trying Five EIZO Monitors in our Editorial Department

- Poor Work Efficiency

- Improve Work Efficiency by Combining an External Monitor with your Notebook PC

- EIZO Monitor Test

- Windows 10 Creators Update

- What is USB Type-C?

- Modern Video Inputs

- Windows 10 Multi-Display Function

- EIZO and Mac – The Perfect Match

- Implementing 4K Monitors

- 10 ways to address eye fatigue caused by displays

- EIZO 4K Monitors – high definition and large screen sizes

- Confused about HiDPI and Retina display? ― Understanding pixel density in the age of 4K

- EIZO Optical Bonding

- How to Address Computer-Related Eye Fatigue

- Pixel Pitch and Enlarged Mode

- Native Resolution and Enlarge Mode

- How can a screen sense touch? A basic understanding of touch panels

- Is the beauty of a curve decisive for color reproduction? Learning about LCD monitor gamma

- Smoother Video with Cutting-Edge Technologies: LCD Monitor I/P Conversion

- Altering color dramatically with a single setting: Examining color temperature on an LCD monitor

- Maximum Display Colors and Look-Up Tables: Two Considerations When Choosing a Monitor

- DisplayPort to D-Sub: The Full Range of LCD Monitor Video Input Interfaces

- The Ability to Display Color Correctly Is Vital: Understanding the Color Gamut of an LCD Monitor

- The Making of a FlexScan Monitor

- Are the response time figures true? A close look at LCD video performance

- The difference in image quality is perfectly obvious! – Let's check the LCD's display

- Making Full Use of the "External" LCD with Laptop Computers

- Videos

- Color Management Resources

- Healthcare Resources

| Introduction | Production Line Characteristics | What's in the Box? |

FlexScan Production Line Characteristics

EIZO's Manufacturing Spirit

|

This phrase pictured was contributed by a worker on the production line, where each EIZO employee motivates the other in order to produce the world’s number one products. With constant awareness for potential problems, our employees work to maintain and improve product quality so that our operations can become better each day. |

|

Employee Expertise

|

Manufacturing the highest quality monitors starts with training our staff so they possess necessary skills before they step onto the factory floor. We have established a training center within our factory where new employees get these skills and veteran employees can acquire new ones. For example, several days of training and a written exam is required before new employees can work on basic assembly tasks. From then supervised training in the factory is required before trainees can work by themselves. More advanced skills such as safety inspections can require even more training. Our training consists of studying written materials followed by "hands-on" practice where workers perfect the skills they will use in the factory. Each time a worker gains a new skill, they receive a sticker for that skill, which is displayed on a board in the training center. Many EIZO manufacturing employees have been with the company for more than a decade. Worker retention is essential to performing specialized tasks. Putting personal importance and worth in our manufacturing process has the added benefits of encouraging creativity, evolution, and making our factory processes ever more efficient, environmentally sound, and globally competitive. |

Students practice drilling in the training center. |

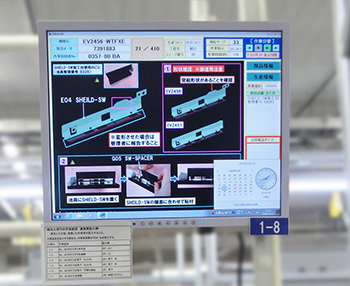

Digital Instructions

|

Each work station on the production line has an overhead screen with instructions about the assembly procedure. This improves productivity because workers do not have to leave the assembly line and consult a printed manual if a question arises about the production process. Since several models are manufactured on the same line in one day, the instructions on the screen change in accordance with the model being produced on the line. |

|

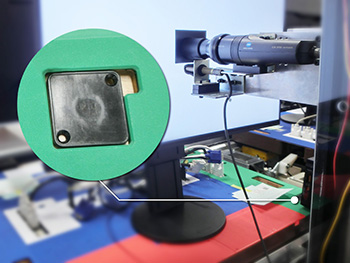

RFID Tag

|

An RFID (radio-frequency identification) tag about 3 cm in width is affixed to the palette on which each monitor is manufactured to ensure the following.

|

|

|

|

The RFID reader scans the RFID in the pallet as it moves along the conveyor, and begins the programmed action automatically. |

| << Introduction | What's in the Box? >> |